When it comes to masonry work, having the right tools is crucial. Masonry involves working with hard, durable materials such as brick, stone, and concrete, which require specialized tools that can handle the job. One such tool is the masonry grinding wheel, a versatile and powerful tool that can cut, sand, and grind a wide range of masonry materials.

Whether you're a professional mason or a DIY enthusiast, a high-quality grinding wheel is an essential tool for any masonry project. In this blog post, we'll take a closer look at masonry grinding wheels, including what they are, how they work, and why they're the perfect tool for tough jobs.

What Are Masonry Grinding Wheels?

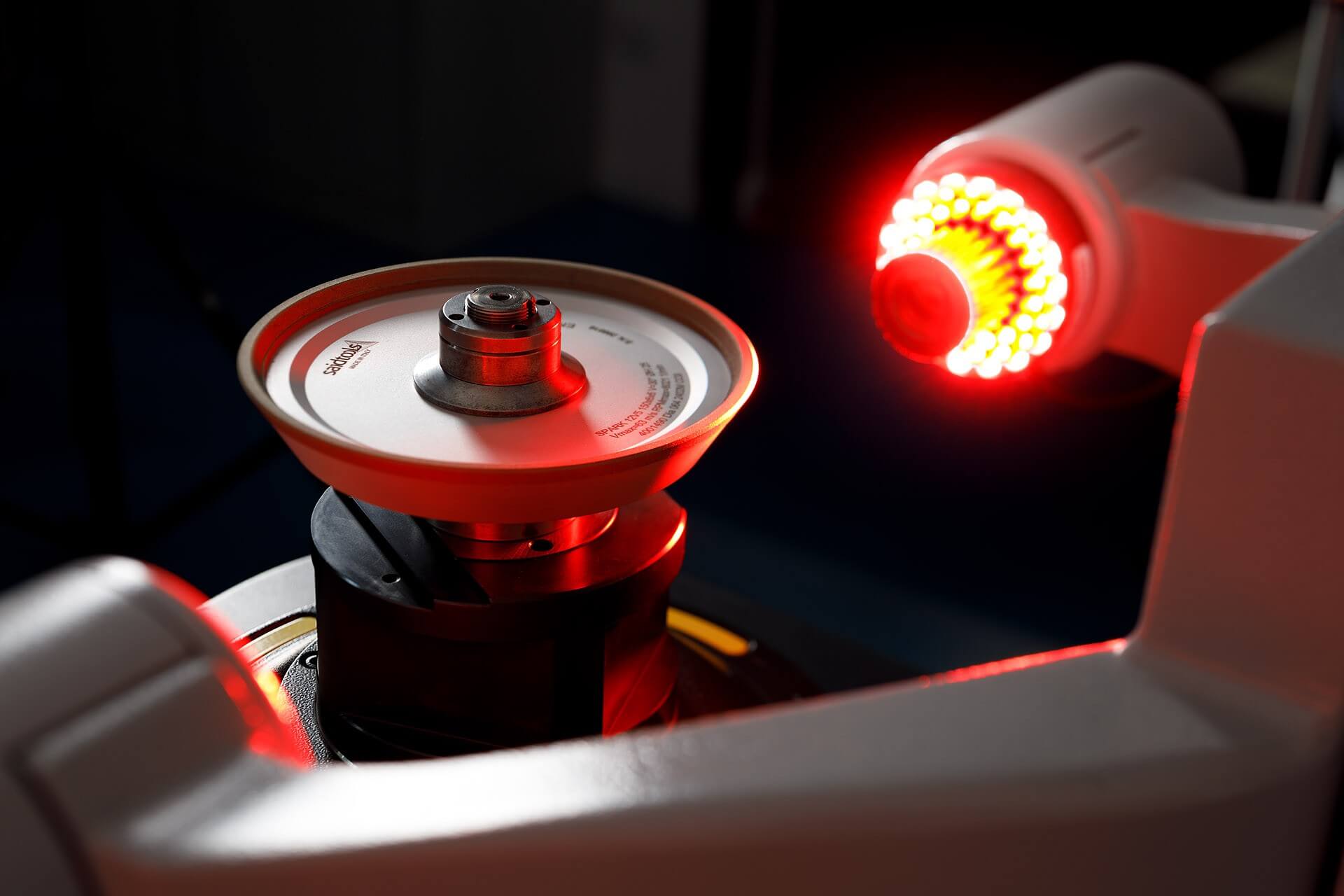

Masonry grinding wheels are specialized tools designed for cutting, sanding, and grinding masonry materials. These wheels are typically made of abrasive materials like diamond or silicon carbide, which allows them to easily cut through hard, dense materials like brick, stone, and concrete.

There are many different types of masonry grinding wheels available, each with their own unique features and benefits. Some common types include:

- Straight wheels: These grinding wheels have a flat face and are used for grinding flat surfaces.

- Tapered wheels: These wheels are tapered from one end to the other, making them ideal for grinding curved surfaces.

- Cylindrical wheels: These grinding wheels have a rounded face and are used for grinding cylindrical or circular surfaces.

- Diamond wheels: These wheels are made with diamond abrasive grains, which allows them to easily cut through hard materials like stone and concrete.

How Do Masonry Grinding Wheels Work?

Masonry grinding wheels work by using abrasive particles to remove material from the surface of the masonry material. The abrasive particles are bonded to the surface of the grinding wheel, and as the wheel rotates, these particles come into contact with the surface of the material being ground.

As the particles come into contact with the material, they create small chips and particles that are then removed from the surface of the material by the grinding wheel. Over time, this process helps to smooth out rough surfaces and create clean, precise cuts.

Why Are Masonry Grinding Wheels the Perfect Tool for Tough Jobs?

Masonry grinding wheels are the perfect tool for tough jobs for several reasons. For one, they are designed specifically for working with hard, dense materials like brick, stone, and concrete. This means that they are capable of cutting through these materials quickly and easily, which can save you time and effort on your projects.

In addition, masonry grinding wheels are also highly versatile tools that can be used for a wide range of applications. Whether you need to cut bricks to size, smooth out rough concrete surfaces, or shape stone for a custom project, a high-quality grinding wheel can help you get the job done.

Another advantage of using masonry grinding wheels is that they are typically very durable and long-lasting. Because they are made with abrasive materials like diamond or silicon carbide, they can withstand a great deal of wear and tear without becoming damaged or worn out. This means that you can trust your grinding wheel to perform consistently over time, even on tough jobs.

Overall, masonry grinding wheels are an essential tool for anyone working with hard, dense materials like brick, stone, or concrete. Whether you're a professional mason or a DIY enthusiast, investing in a high-quality grinding wheel can help you achieve clean, precise cuts and smooth, finished surfaces on all of your masonry projects.